Sustainability

As responsible producers, flour millers work continuously to improve their environmental performance and reduce their impacts on the environment.

Sustainable Foods Event 2026

We're partnering with Sustainable Foods 2026 for their event taking place at the Business Design Centre, London on 28-29 January 2026. With sustainability high on the global agenda, this is a must-attend event for those shaping the future of food, including flour millers, those working at flour mills, and other industry players.

At event will explore key themes including:

- Food security and financing the transition

- Health and sustainability integration

- Regenerative agriculture and soil health

- Net zero supply chains and food waste solutions

- Consumer behaviour, water scarcity, and more

You can download the agenda highlights here.

As partners, UK Flour Millers' members and associate members can book now and save 10%. Save your spot today!

Environmental impacts

Flour milling is energy intensive; the process is centred on breaking open the wheat kernel and progressively refining it to meet customer specifications for bread making and other uses. The process uses electricity to power rollers, sieves, and other machinery across the mill. Flour millers closely focus on energy efficiency to ensure that its use and associated costs are kept as low as possible.

As a manufacturing process, flour mills in the United Kingdom (UK) operate under environmental permits, issued under the Industrial Emissions Directive by the Environment Agency, Scottish Environmental Protection Agency, or the Northern Ireland Environment Agency.

Millers operate dust filters across their mills to manage emissions of dust; noise generation is also tightly controlled.

Flour milling: a zero-waste process

Millers process wheat into flour. The process of milling splits the white endosperm which makes up the bulk of the kernel from the outer layers, the bran. The flour goes into making bread and other food products and the bran is used either in breakfast cereals or other baked goods; it is also widely used in animal feed.

The only waste from the milling process is the adventitious materials which have come in with the grain, which can include stones. These are removed as part of pre-milling screening before the wheat is processed.

Environmental performance management

All flour millers run environmental management systems (EMS) to track and manage their environmental performance. The management systems, independently audited to ISO14001, are founded on the principle of continuous performance improvement.

Local communities

Flour mills have often been central to their local communities for generations. Our members are good neighbours, supporting their communities and engaging over any questions or concerns.

Climate change

All primary processors of food, including flour millers in the UK, are affected by climate change. The increasing variability in weather patterns and the more frequent extreme weather conditions can have a major impact on growing conditions and consequently on grain quantity and grain quality.

Grains such as wheat, barley, rye, and oats are the indispensable raw material to produce flour that will be used in bread and other final products. Millers produce flour to strict customer specifications and in the UK, we are working with the whole supply chain (breeders, farmers, merchants, retailers) to find solutions to produce more resilient wheat with less impact on the environment.

Carbon footprint

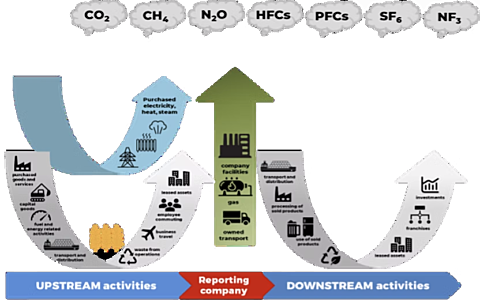

Flour milling activities which generate carbon include growing wheat, transporting it to the mill, processing it into flour, and then shipping it on to customers. The carbon footprint of milling is the total amount of greenhouse gases (GHG) emissions that are produced in these activities.

All activities, from farm to mill to bakery, have a carbon footprint. A distinction is made amongst the emissions between those which are direct emissions and indirect emissions (see diagram).

The main gases are carbon dioxide (CO2), methane (CH4), nitrous oxide (N2O), and hydrofluorocarbons (HFCs). These emissions are expressed in equivalent tons of CO2 (CO2e).

UK flour millers are working on the progressive reduction of their Scopes 1 and 2 emissions (see diagram), reflected by progress in renewable energy and energy efficiency.

Scope 3 emissions (see diagram) are more complex to address and making progress in this area is one of the main focuses of UK flour millers. The principal contributor to millers’ scope 3 emissions is the faming of the main raw material, wheat, which has been estimated to represent more than 60% of flour’s carbon footprint.

-

UK Flour Millers Sustainability Agenda 2025

This statement marks a crucial step forward in addressing sustainability challenges for all millers. Every business brings unique perspectives and expertise, which enrich collective efforts and drive innovation. Learn more in our built out sustainability strategy document.

-

UK Flour Millers Sustainability Strategy 2025

As an essential part of the UK’s food supply chain, the milling industry plays a critical role in supporting sustainability. Beyond environmental efforts, the industry also plays a key role in the social and economic fabric of this supply chain. Learn more in our sustainability agenda document.