Statistics

Wheat flour is an important bedrock of the UK diet. This single ingredient is in about a third of all grocery products on supermarket shelves and provides 20% of the energy and protein consumed by the UK population. Additionally, flour makes a significant contribution to vitamin and mineral intake providing much of the fibre, calcium (great news for vegans) and iron (more great news for vegans) consumed in the UK. Flour is an ingredient with much to offer.

The quantities of flour milled and consumed in the UK each day are vast. About 12 million loaves of bread, 2 million pizzas, and 10 million cakes and biscuits are made in Britain every day. Furthermore, data from Kantar shows that bread is purchased by more UK households than any other product – even toothpaste.

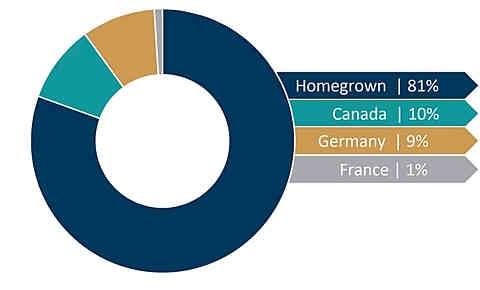

To meet demand, the UK flour milling industry processes 6.2 million tonnes of wheat to produce almost 5 million tonnes of flour every year. The industry is the largest single processor of British wheat. In 2019/20 the proportion of homegrown wheat used by flour millers was 87% equalling the all-time high previously seen in 2011. However a small harvest in 2020 with a reduction in quality means that the proportion of homegrown wheat is expected to fall to 76% in 2020/21.

You can download a full version of our Facts and Figures leaflet here Download

Wheat Usage & Flour Production (000 tonnes)

| 1991/92 | 2001/02 | 2011/12 | 2019/20 | 2021/22 (e) |

|---|---|---|---|---|---|

| Total UK wheat harvest | 14,321 | 11,800 | 15,257 | 16,225 | 15,664 |

| Total wheat usage* | 4,984 | 5,631 | 6,816 | 6,057 | 5,934 |

| Home grown usage | 3,903 | 4,657 | 6,135 | 5,293 | 4,833 |

| EU usage | 831 | 417 | 327 | 227 | 539 |

| Third country usage | 250 | 556 | 354 | 537 | 562 |

| Total flour production | 3,825 | 4,438 | 4,804 | 4,803 | 4,651 |

*Prior to 2012/13 usage includes malt, seeds and breakfast cereals. Figures include starch and biofuel production.

Flour type (%)

| White breadmaking | 53.9 | 53.5 | 52.0 | 50.5 | 52.4 |

|---|---|---|---|---|---|

| Brown breadmaking | 3.9 | 3.0 | 2.2 | 1.1 | 0.9 |

| Wholemeal breadmaking | 6.2 | 4.9 | 7.0 | 4.5 | 4.3 |

| Biscuit | 14.1 | 12.2 | 12.1 | 9.7 | 9.7 |

| Cake | 1.6 | 1.7 | 2.5 | 1.6 | 1.7 |

| Pre-packed (household flour) | 3.2 | 3.1 | 2.7 | 4.3 | 4.1 |

| Food ingredient | - | 5.0 | 3.7 | 8.6 | 8.3 |

| Self-raising | 2.6 | - | - | - | - |

| Starch manufacture and other | 14.5 | 16.6 | 17.7 | 19.9 | 18.7 |

Supporting Britain's Farmers

The UK's flour millers are the single biggest user of homegrown wheat. In a typical year they would purchase around 5.5million tonnes from Britain's cereal farmers

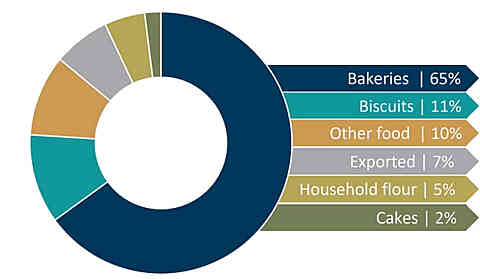

Supporting Britain's Food

Most of the flour produced in the UK goes into bread. However flour is an ingredient in around 30% of all food in the UK

Environmental impact

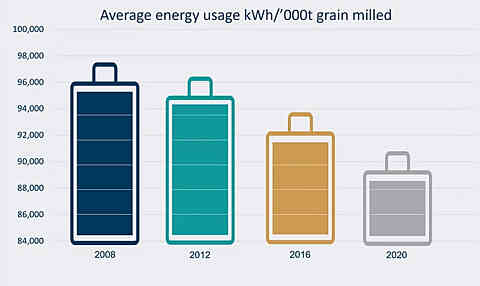

Our industry has a very low environmental impact. The milling process produces almost no waste, therefore the main impacts come from the energy used during milling and the transportation of flour to bakeries and retailers.

UK Flour Millers has been collecting data on environmental impact since 2008 and figures from 2020 show a positive and improving picture of the sector's Scope 1 and Scope 2 performance (ie those factors which are under the control of the business).

10% Reduction in Energy Use

There has been significant improvement in energy efficiency, with milling sites now using approximately 10% less electricity per thousand tonnes of grain milled than in 2008.

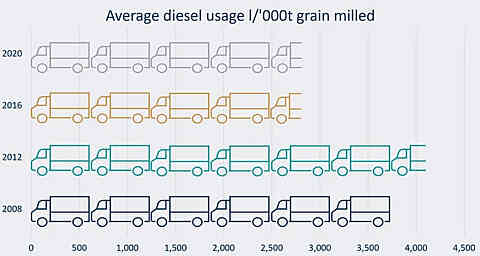

25% Reduction in Diesel Use

In the same time there was significant increase in fuel efficiency with millers using 25% less diesel in 2020 compared to 2008 data. This was achieved by using more efficient vehicles, driver training and more efficient use of space in trucks and tankers.

Near Zero Waste Process

Nearly all the raw material that enters a flour mill is used - 80% is made into flour, 18% goes on to animal feed and 1% to bran and germ. The sector generates very little waste - 0.3% of total output.

Of the waste that is generated, most is destined for recycling. Only a tiny proportion goes to landfill, representing just 0.007% of total output by weight. This is equivalent to one skip per mill per year for the average UK mill.

Waste as a proportion of output

| Recycling | 0.180% |

|---|---|

| Compost | 0.075% |

| Energy | 0.036% |

| Landfill | 0.007% |

Quality, Safety & Assurance

Millers take great care in producing exactly the right flour for each customer, meaning that there are more than 400 types of flour produced in the UK.

In order to meet specific customer requirements, flour millers need to know the exact qualities of the wheat they purchase. In a year, 172,000 lorry loads of wheat are tested by millers, generating over 1.5million points of data, which are used to determine which wheats should be selected, blended and milled to produce the required flour.

In addition to quality assessments, millers test wheat for contamination to ensure stringent food safety criteria are met.

Some tests are carried out as wheat arrives at mills, whereas others are done within rolling programmes of analysis funded by the industry. Comparing these data over months and years allows identification of areas that require attention, part of a collaborative system designed to deliver world-class food safety standards.

Millers also participate in proficiency schemes and ring-checks to ensure equipment is working properly and that staff are testing accurately. These data are discussed at an industry level to guarantee the whole sector is testing to a high standard.

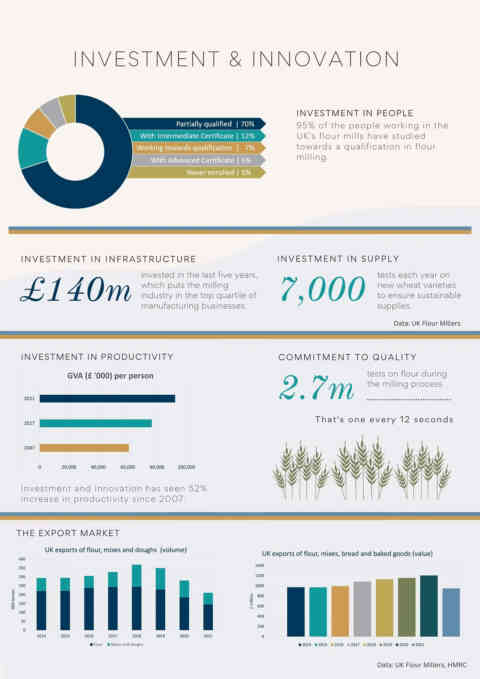

People and Skills

The flour milling sector has consistently invested in its people. Every year, between 5% and 10% of the industry’s workforce are enrolled on at least one of the UK Flour Millers world renowned distance learning courses. More bespoke programmes for developing senior staff are available, and businesses also invest in company specific schemes. Average earnings are well above the norm for food manufacturing and on a par with advanced engineering sectors such as aerospace – further evidence of industry investment in its workforce. To support on-demand learning and create a central hub for all the industry’s training, UK Flour Millers has invested heavily in the development of a virtual flour mill; in addition we are developing new micro learning packages to better enable our people to fit short bursts of study into their schedules and support them as they work towards formal qualifications.

Innovation and Investment

Despite being an ancient tradition, flour millers are proud of the long-standing culture of innovation on which the industry thrives. As far back as 1901, millers embarked on a programme to assess the suitability of wheat varieties grown in the UK for flour milling – work that continues to this day as part of an integrated programme to test new varieties.

Some 7,000 tests are carried out annually on the suitability of new varieties for milling and baking. The resulting improved quality and reliability of homegrown wheat has led to the high usage of domestic wheat, which helps ensure wheat flour remains a reliable, stable and sustainable ingredient thereby improving the nation’s food security.

Imported wheat – sourced mostly from Germany, Canada and France – is milled mainly for quality characteristics that cannot currently be found in domestic varieties.

UK flour millers have invested heavily in new and renewed facilities during the last 10-years. This has delivered improved efficiency and led to steadily improving labour productivity – around 2.5% per year compared with the average in UK manufacturing of

0.5% and 0.9% in food manufacturing over the same period (source: ONS). The Gross Value Added (GVA) per employee in flour milling is 50% higher than the average in food and drink manufacturing as a whole; and 52% higher than in our sector in 2007.